The Right Way™ to Avoid Leaks

S-5! brackets are designed with state-of-the-art sealant technology and have been certified effective for watertight performance through the ASTM E2140 static water pressure test.

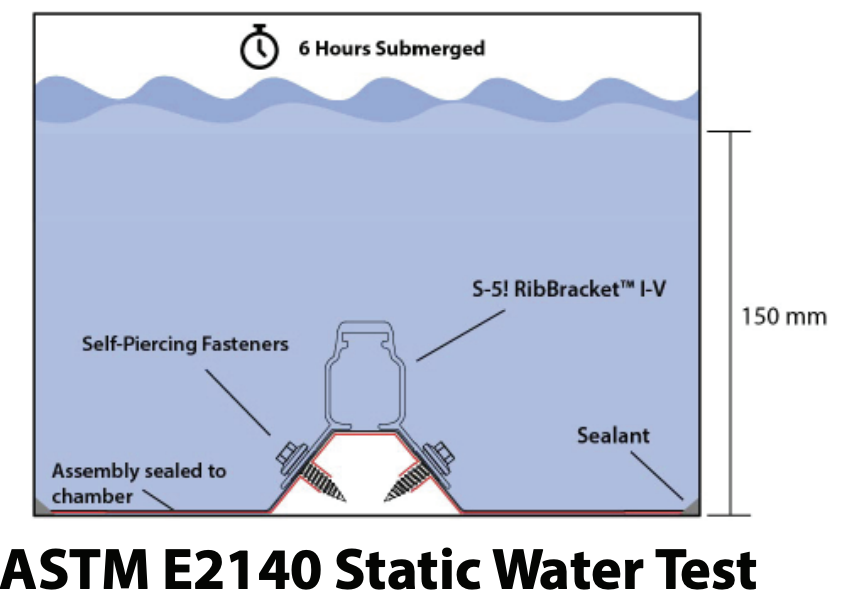

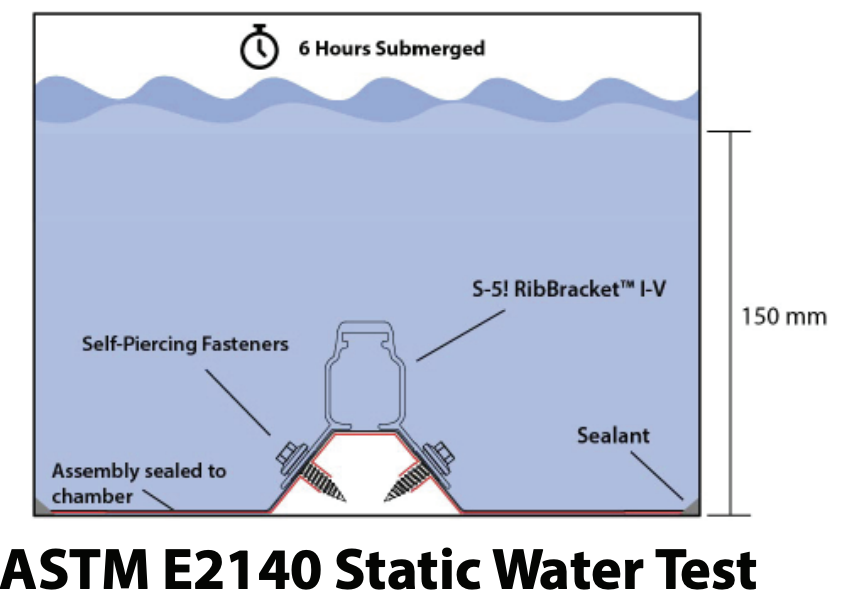

ASTM E2140 Water Penetration Test

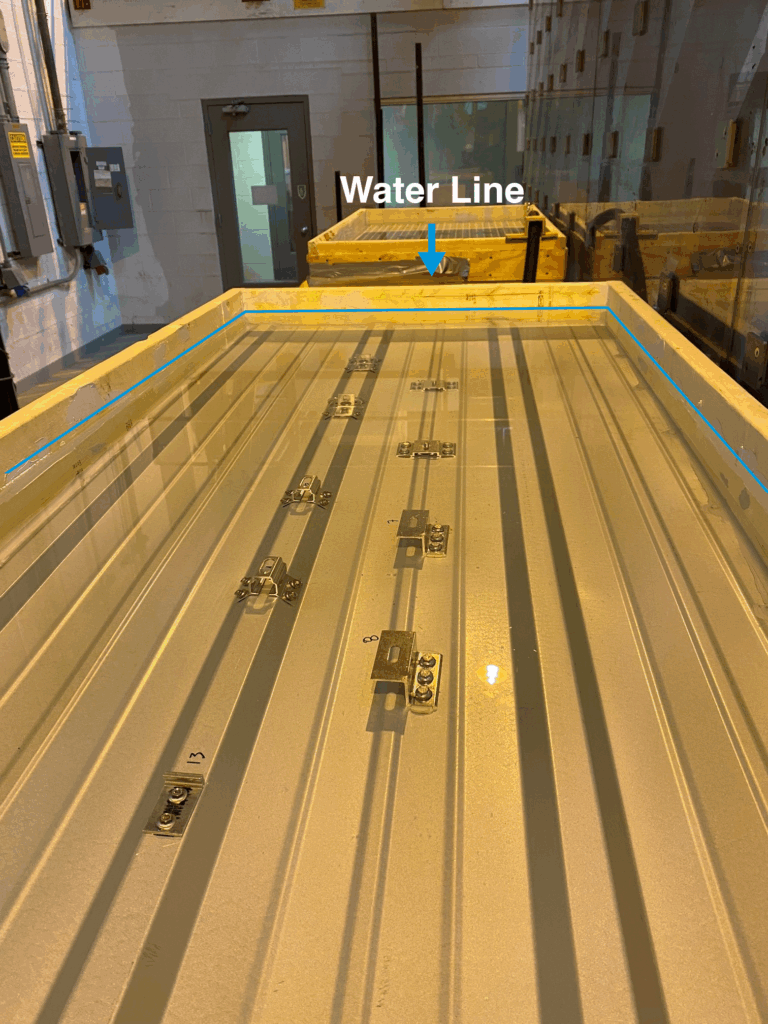

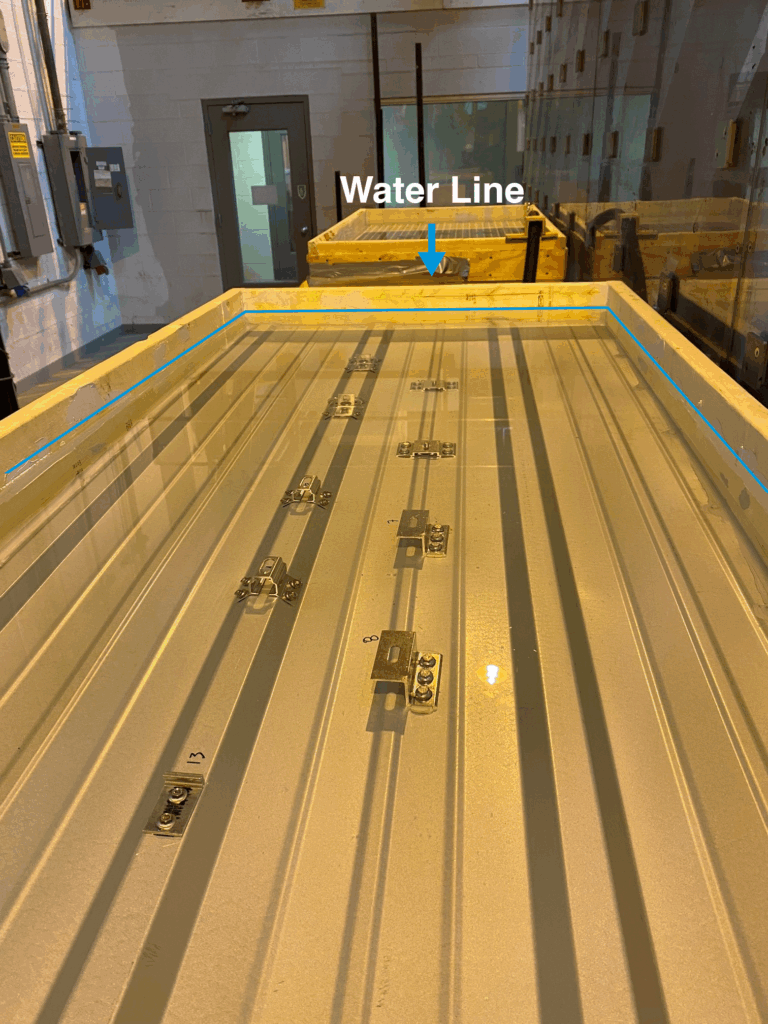

Independent water infiltration testing is the only way to ensure roof attachments perform as intended. Few manufacturers conduct these tests, but ASTM E2140 is the most rigorous and preferred standard for low-slope metal roofing. It simulates real-world conditions using full-size roof assemblies under 150 mm of water pressure for six hours. One drop of leakage means failure. If a product hasn’t passed ASTM E2140, it shouldn’t go on your roof.

Superior Sealant Technology

Closed-cell ethylene propylene diene monomer (EPDM) is a superior rubber compound that offers high tensile strength, a long lifespan and resistance to high rooftop temperatures. Our attachments utilize factory-applied EPDM pads that are adhered to the feet of the brackets. This offers reliable waterproofing, in contrast to unstable in-field applications that eventually dry out and lead to leaks. EPDM is so durable that it’s even used as pond liners. To enhance the EPDM’s longevity, our bracket design conceals the sealant, safeguarding it from UV exposure and degradation.

Our accompanying self-piercing screws feature EPDM washers beneath the screw head to prevent moisture intrusion at penetration points. This means you obtain a “double seal” with the EPDM washer on the fasteners from above and the pre-applied EPDM on the feet of the brackets below.

S-5! brackets submerged under 6 inches (152 mm) of water.

The Importance of Verified Testing

When installing rooftop equipment, it's crucial to ensure the attachments won't cause damage or corrosion. How can you be confident that the attachments will keep moisture out? Choose components with cutting-edge sealant technology and watertight effectiveness through the ASTM E2140 static water pressure test!

Mount With Confidence

We care about the longevity of your roof, so we have done the work to create attachments you can trust. Our factory-applied EPDM sealant on our brackets, combined with our specially designed self-piercing screws, is engineered for performance and has been proven by third-party testing not to leak.

PVKIT® and RibBracket™ I-V rail-less solar mounting.